Zaɓin damahex bolt da goroyana da mahimmanci don tabbatar da dawwamar kayan aikin gini. Zaɓuɓɓuka mara kyau na iya haifar da rarraba nauyin zaren mara daidaituwa, kamar yadda binciken Motosh ya bayyana, wanda ya gano kayan goro mai laushi a matsayin abin da ke taimakawa. Gwajin gajiyar Kazemi ya kara bayyana cewa lodin axial da yawa yana rage tsawon rayuwa, yana mai jaddada mahimmancin abu da ƙira. High quality fasteners, kamargarma guntu da goro, waƙa da kusoshi da goro, kokashi bolt da goro, hana kasawa akai-akai, adana kuɗi akan lokaci. Zaɓin da ya dace yana haɓaka ɗorewa, yana rage kulawa, kuma yana haɓaka aiki a cikin mahalli masu buƙata.

Key Takeaways

- Zabar dadama abu don kusoshikuma goro yana da mahimmanci. Bakin karfe yana tsayayya da tsatsa da kyau, yayin da carbon karfe yana da rahusa da ƙarfi.

- Sanin iyakokin kaya shine mabuɗin don aminci. Koyaushe ɗauki maɗaurai waɗanda suka hadu ko suka wuce nauyin da ake buƙata don aikin ginin ku.

- Madaidaicin girman da nau'in zaren suna yin haɗin gwiwa mai ƙarfi. Yi amfani da sigogi masu girma da kayan aiki kamar masu mulki don bincika ma'auni kafin amfani da su.

- Sayayyamai kyau-ingancin fastenersyana adana kuɗi akan lokaci. Kayan aiki masu ƙarfi suna buƙatar ƙarancin gyarawa kuma kiyaye kayan aiki ya daɗe.

- Duba kayan ɗamara sau da yawa yana taimakawa wajen guje wa matsaloli. Nemo lalacewa, tsatsa, da ingantaccen ƙarfin lodi don kiyaye kayan aikin ginin ku lafiyayye.

Zaɓin kayan abu don Hex Bolt da Nut

Kayayyakin gama gari da Kayayyakinsu

Zaɓin kayan da ya dacega hex bolt da goro yana da mahimmanci don tabbatar da dorewa da aiki a aikace-aikacen gini. Kowane abu yana ba da kaddarorin musamman waɗanda suka sa ya dace da takamaiman amfani. A ƙasa akwai kwatancen kayan da aka saba amfani da su:

| Kayan abu | Amfani | Rashin amfani |

|---|---|---|

| Bakin Karfe | Kyakkyawan juriya na lalata; dace don aikace-aikacen waje da na ruwa | Ya fi tsada fiye da karfe na yau da kullum |

| Karfe Karfe | Mai ƙarfi kuma mai dorewa; m | Yana iya buƙatar sutura don kariyar tsatsa |

| Titanium | Kyakkyawan rabo mai ƙarfi zuwa nauyi; dace da matsanancin yanayi | Mafi girman farashi; ba za a iya amfani da shi sosai ba |

Bakin karfe ya yi fice don juriya na lalata, yana mai da shi manufa don yanayin waje da na ruwa. Karfe na carbon, a gefe guda, zaɓi ne mai tsada wanda ke ba da ƙarfi da ƙarfi amma galibi yana buƙatar ƙarin sutura don hana tsatsa. Titanium, ko da yake ba kowa ba ne, yana ba da ma'aunin ƙarfi-zuwa nauyi na musamman, yana sa ya dace da matsanancin yanayi.

Fahimtar waɗannan kaddarorin yana taimakawa wajen zaɓar kayan da ya fi dacewa don gunkin hex da goro, yana tabbatar da abubuwan ɗaure da buƙatun yanayin gini.

Zabar Kayayyaki don Musamman Muhalli

Yanayin da za a yi amfani da guntun hex da goro yana tasiri sosai wajen zaɓin kayan. Don aikace-aikacen waje ko na ruwa, bakin karfe galibi shine zaɓin da aka fi so saboda kariyar oxide mai kariya wanda ke hana iskar oxygen da lalata. Wannan fasalin yana haɓaka tsawonsa kuma yana rage farashin kulawa akan lokaci.

A cikin yanayin zafi mai zafi ko sinadarai masu tayar da hankali, gami da karfe tare da murfin foda na baki yana da tasiri sosai. Rufin ba kawai yana inganta juriya na lalata ba amma yana ƙara yawan zafin jiki, yana sa ya dace da aikace-aikacen da ake buƙata. Don dalilai na gine-gine na gabaɗaya, ƙarfe na carbon ya kasance sanannen zaɓi saboda iyawar sa da haɓakarsa, kodayake yana iya buƙatar galvanization ko plating zinc don ƙarin kariya.

Tukwici: Koyaushe la'akari da yanayin muhalli, kamar zafi, zafin jiki, da fallasa zuwa sinadarai, lokacin zabar kayan don kusoshi na hex da kwayoyi. Wannan yana tabbatar da masu haɗin gwiwa suna kiyaye amincin su da aikin su na tsawon lokaci.

Fa'idodin Karfe Bakin Karfe, Karfe Carbon, Da Garin Karfe

Kowane kayan yana ba da fa'idodi daban-daban waɗanda ke biyan buƙatun gini daban-daban:

- Bakin Karfe: An san shi don juriya na musamman na lalata, bakin karfe yana da lissafin sama da 30% na duk abubuwan da ake amfani da su a cikin gini. Matsakaicin girman ƙarfinsa zuwa nauyi yana ba da damar sassauƙan sassa, rage amfani da kayan aiki da tasirin muhalli. Bugu da ƙari, ƙarfinsa yana haifar da ƙananan farashin kulawa, yana mai da shi zaɓi mai tsada a cikin dogon lokaci.

- Karfe Karfe: Ana amfani da wannan abu sosai a cikin gine-gine saboda ƙarfinsa da araha. Yana da manufa don aikace-aikace inda farashi ke da damuwa amma ƙarfin ba zai iya lalacewa ba. Tare da suturar da ta dace, ma'aunin ƙarfe na carbon zai iya jure wa yanayi mai tsanani, yana tabbatar da tsawon rai.

- Alloy Karfe: Bayar da ingantattun kayan aikin injiniya, gami da ƙarfe ya dace da aikace-aikacen da ake buƙata. Itshigh tensile da kuma samar da ƙarfisanya shi dacewa da kayan aiki masu nauyi da kayan aikin tsari. Zane na dogayen kwayoyi a cikin kayan haɗin ƙarfe na ƙarfe yana rage matsa lamba akan zaren, haɓaka ƙarfin haɗin gwiwa da kwanciyar hankali.

Ta hanyar fahimtar amfanin waɗannan kayan, masu sana'a na gine-gine na iya yin yanke shawara mai mahimmanci wanda ke inganta aikin da kuma tsawon lokacin kayan aikin su.

Ƙimar Ƙarfi da Ƙarfi

Fahimtar Kimar Load

Ƙimar lodi ta ƙayyade iyakar ƙarfin hex da goro za su iya jurewa ba tare da gazawa ba. Waɗannan ƙimar suna da mahimmanci don tabbatar da aminci da amincin kayan aikin gini. Injiniyoyi suna ƙididdige ƙididdige ƙididdigewa bisa dalilai kamar ƙarfin abu, girman ƙugiya, da ƙirar zaren. Don aikace-aikacen gini masu nauyi, masu ɗaure dole ne su hadu da takamaiman nauyin hujja da buƙatun taurin don ɗaukar matsananciyar damuwa.

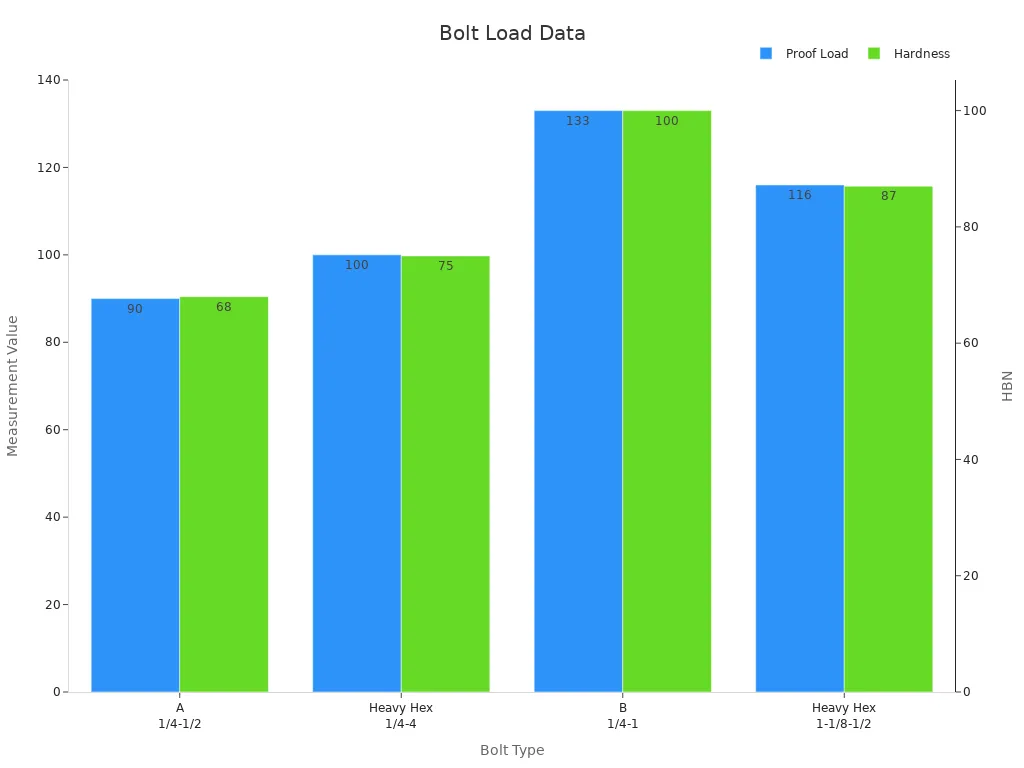

Teburin da ke ƙasa yana ba da haske game da ƙimar hujja da bayanan tauri don maki daban-daban da salon bolts na hex da goro:

| Daraja | Salo | Girman (a.) | Ɗaukar Hujja (ksi) | Hardness (HBN) |

|---|---|---|---|---|

| A | Hex | 1/4 - 1-1/2 | 90 | 68 |

| Hex mai nauyi | 1/4 - 4 | 100 | 75 | |

| B | Hex mai nauyi | 1/4 - 1 | 133 | 100 |

| Hex mai nauyi | 1-1/8 - 1-1/2 | 116 | 87 |

Lura: Kwayoyin hex masu nauyi sun fi daidai gwargwado na hex, suna ba da ƙarfin ɗaukar nauyi kamar yadda ASTM A563 ya dace.

Fahimtar waɗannan ƙididdiga yana taimaka wa ƙwararrun gini su zaɓi na'urorin haɗi waɗanda suka yi daidai da buƙatun injiniyoyi na kayan aikin su, yana tabbatar da dorewa da aminci.

Ka'idojin Masana'antu don Ƙarfin Ƙarfi

Matsayin masana'antu suna taka muhimmiyar rawa wajen ayyana aiki da amincin naúrar ƙarfi mai ƙarfi. Waɗannan ƙa'idodi suna tabbatar da daidaito a cikin masana'anta kuma suna ba da maƙasudi don kimanta ƙarfin ƙarfi, tauri, da dorewa. A ƙasa akwai wasu ƙa'idodi masu mahimmanci na hex bolts da goro da ake amfani da su wajen gini:

| Daidaitawa | Bayani | Ƙarfin Ƙarfin Ƙarfin Ƙarfi |

|---|---|---|

| Saukewa: A354-17E2 | Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙa ) Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙa, Ƙarƙai, da Masu Fasteners | N/A |

| F2882/F2882M-17 | Alloy Karfe Screws, Zafi Magani | 170 ksi / 1170 MPa |

| F3125/F3125M-25 | Ƙarfafa Tsarin Ƙarfi da Taro | 120 ksi, 144 ksi, 150 ksi / 830 MPa, 1040 MPa |

| F3043-23 | Juya Kashe Nau'in Tattalin Arzikin Ƙarƙashin Ƙarfafawa | 200 ksi |

| F3111-23 | Babban Hex Structural Bolt/Nut/Washer Majalisar | 200 ksi |

| F3148-17 (2024) | Babban Ƙarfi na Ƙarfafa Ƙarfafa Ƙarfafawa | 144 ku |

Waɗannan ƙa'idodi, kamar ASTM F3125 da F3043, suna tabbatar da cewa masu ɗaure sun cika buƙatun inji don aikace-aikacen nauyi. ƙwararrun gine-gine ya kamata koyaushe su tabbatar da bin waɗannan ƙa'idodi yayin zabar kayan ɗamara don ayyuka masu mahimmanci.

Aikace-aikace Masu Bukatar Ƙarfin Hex Bolts da Kwayoyi

Babban ƙarfi hex bolts da goro suna da mahimmanci a aikace-aikace inda kaya masu nauyi da matsananciyar yanayi suke. Ana yawan amfani da waɗannan fasteners a:

- Haɗin Tsarin Karfe: Ƙarfin ƙarfi mai ƙarfi yana tabbatar da katako da ginshiƙai a cikin gine-gine da gadoji, tabbatar da kwanciyar hankali a ƙarƙashin nauyin nauyi.

- Manyan Injina: Kayan aiki kamar na'urorin tono da cranes sun dogara da na'urori masu ɗorewa don ɗaukar damuwa na aiki da rawar jiki.

- Tsire-tsire masana'antu: Kayan aiki tare da yanayin zafi mai zafi ko ɓarna suna buƙatar kayan ɗamara da aka yi daga ƙarfe mai ƙarfe ko bakin karfe don haɓaka aikin.

- Ginin Ruwa: Bakin karfe masu ɗaure suna tsayayya da lalata a wuraren ruwan gishiri, yana mai da su manufa don docks da dandamali na teku.

Jadawalin da ke ƙasa yana kwatanta alakar da ke tsakanin nauyin hujja da taurin maki daban-daban, yana mai jaddada mahimmancin zaɓin abin ɗamara mai kyau don takamaiman aikace-aikace:

Zaɓin madaidaicin hex da goro don waɗannan aikace-aikacen yana tabbatar da tsawon rai da amincinkayan aikin gini. ƙwararrun ƙwararrun dole ne suyi la'akari da ƙimar lodi, ƙimar masana'antu, da abubuwan muhalli don yanke shawara mai fa'ida.

Ƙayyadaddun Girma da Zare

Zaɓin Madaidaicin Girman Kayan Gina

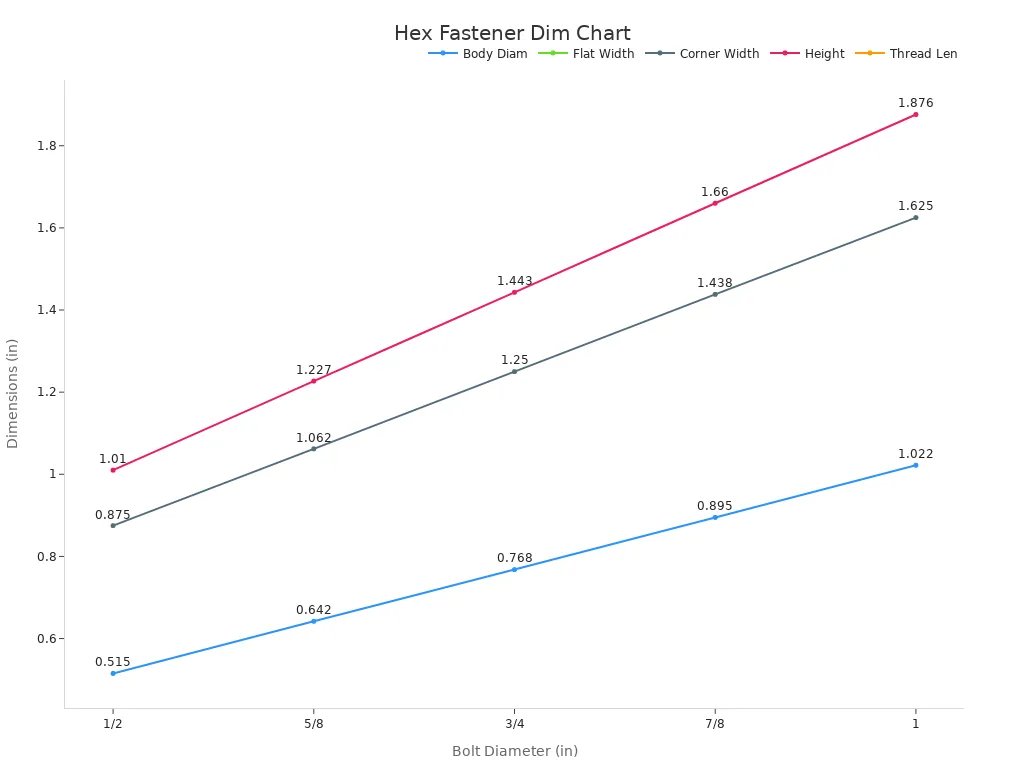

Zaɓin madaidaicin girman hex bolt da goro yana da mahimmanci don tabbatar da amintaccen haɗin gwiwa a cikin kayan gini. Girman girman yana tasiri kai tsaye ikon maɗauri don ɗaukar kaya da kiyaye amincin tsari. Siffofin ƙididdiga da bayanan haƙuri suna ba da jagora mai mahimmanci don zaɓar girman da ya dace. Teburin da ke ƙasa yana zayyana maɓalli na maɓalli don masu ɗaure hex:

| Diamita na Bolt | Diamita na Jiki | Nisa Tsakanin Filayen | Nisa Ketare Kusurwoyi | Tsayi | Tsawon Zaren |

|---|---|---|---|---|---|

| 1/2 | 0.515 | 7/8 | 0.875 | 1.010 | 5/16 |

| 5/8 | 0.642 | 11/16 | 1.062 | 1.227 | 25/64 |

| 3/4 | 0.768 | 11/4 | 1.250 | 1.443 | 15/32 |

| 7/8 | 0.895 | 17/16 | 1.438 | 1.660 | 35/64 |

| 1 | 1.022 | 15/8 | 1.625 | 1.876 | 39/64 |

Tukwici: Koyaushe koma zuwa sigogi masu girma dabam don tabbatar da zaɓaɓɓen abin ɗamara ya dace da buƙatun kayan aiki.

Zaren Pitch da La'akari da dacewa

Fitar zaren da dacewataka muhimmiyar rawa a cikin jituwa na hex bolts da goro. Fitilar zaren yana nufin nisa tsakanin zaren, yayin da dacewa ke ƙayyade yadda kusoshi da kwaya suka yi tauri. Rashin daidaituwa a cikin farawar zaren zai iya haifar da ɗaure mara kyau, rage ƙarfin haɗin gwiwa. Don kayan aikin gine-gine, yawancin zaren zaren sun fi so saboda tsayin daka da tsayin daka da sauƙi na haɗuwa.

Jadawalin da ke ƙasa yana kwatanta alakar da ke tsakanin diamita na bolt da ma'aunin zaren, yana taimaka wa ƙwararru su zaɓi abin da ya dace don aikace-aikacen su:

Aunawa da Daidaita Hex Bolts da Kwayoyi

Daidaitaccen ma'auni suna da mahimmanci don daidaita ma'aunin hex da goro. Yin amfani da kayan aikin da suka dace yana tabbatar da dacewa da dacewa kuma yana hana gazawar inji. Abubuwan da aka ba da shawarar sun haɗa da:

- Calipers: Auna diamita, tsayi, da girman kai tare da daidaito.

- Ma'aunin Zare: Ƙayyade filin zaren don tabbatar da dacewa.

- Mai Mulki ko Ma'aunin Tef: Da sauri auna jimlar tsayin kusoshi.

Daidaita waɗannan kayan aikin yana da mahimmanci don kiyaye daidaito. Kayan aikin da aka daidaita akai-akai suna rage kurakurai, suna tabbatar da masu ɗaure sun cika ƙayyadaddun da ake buƙata.

Pro Tukwici: Koyaushe tabbatar da ma'auni kafin shigarwa don guje wa madaidaicin madaidaicin, wanda zai iya lalata amincin kayan aiki.

Rufi da Ƙarshe don Dorewa

Muhimmancin Juriya na Lalata

Juriya na lalata yana taka muhimmiyar rawa wajen tsawaita tsawon rayuwar na'urorin da ake amfani da su a cikin kayan gini. Abubuwan muhalli kamar danshi, canjin zafin jiki, da fallasa ga sinadarai na iya hanzarta lalata kayan haɗin gwiwa. Lalacewar ɗakuna suna yin sulhu da daidaiton tsarin kayan aiki, wanda ke haifar da yuwuwar gazawar da gyare-gyare masu tsada. Zabasuturar da ke ba da kariya ta lalata mai tasiriyana tabbatar da cewa fasteners suna kula da ƙarfinsu da aikin su akan lokaci.

Misali, a cikin muhallin waje, galibi ana fallasa na'urori ga ruwan sama, zafi, da gurɓata yanayi. Rubutun yana aiki azaman shinge mai kariya, yana hana iskar oxygen da samuwar tsatsa. Wannan yana da mahimmanci musamman ga guntun hex da goro, saboda waɗannan abubuwan haɗin gwiwa suna da mahimmanci wajen riƙe manyan injuna da sifofi tare. Ta hanyar ba da fifiko ga juriya na lalata, ƙwararrun gini na iya rage bukatun kulawa da haɓaka amincin kayan aiki.

Kwatanta Plating na Zinc, Galvanization, da sauran Rubutun

Daban-daban masu sutura suna ba da fa'idodi na musamman kuma sun dace da takamaiman aikace-aikace. Teburin da ke ƙasa yana haskaka mahimman fasali da aikace-aikacen sutura na gama gari:

| Nau'in Rufi | Mabuɗin Siffofin | Aikace-aikace |

|---|---|---|

| Tufafin Zinc | Kariyar lalatar hadaya, kyakkyawan juriya na yanayi, mai tsada | Motoci, Gine-gine, Kayan Aiki masu nauyi |

| Rufin Phosphate | Shamaki a kan lalata, yana haɓaka mannewa fenti, juriya mai matsakaici | Abubuwan da ke buƙatar ƙarin sarrafawa ko ƙarewa, inda manne fenti ke da mahimmanci |

Tufafin Zinc suna ba da kariya ta hadaya, ma'ana suna lalata a madadin na'urar, ta haka ne ya kara tsawon rayuwarsa. Wannan ya sa su dace don ginin gaba ɗaya da kayan aiki masu nauyi. Rubutun phosphate, a gefe guda, yana haifar da shinge ga lalata da inganta fenti, yana sa su dace da abubuwan da ke buƙatar ƙarin ƙarewa.

Lokacin kwatanta plating na zinc da galvanization, ma'aunin aiki yana bayyana bambance-bambance masu mahimmanci a cikin dorewa. Abubuwan da aka yi amfani da su da kyau na galvanized na iya wucewa sama da shekaru 50 a yankunan karkara da shekaru 20 zuwa 50 a wuraren masana'antu. Plating na Zinc, yayin da yake da tsada, ƙila ba zai yi kyau ba a cikin yanayi mara kyau kamar yanayin ruwa, inda babban danshi da gishiri ke haɓaka lalata. Abubuwa kamar kauri mai rufi, bayyanar muhalli, da ayyukan kiyayewa suma suna tasiri da tsayin waɗannan ƙarewa.

Daidaita Kuɗi da Inganci

Fa'idodi na Dogon Zamani na Manyan Fasteners

Zuba jari a cikihigh quality fastenersyana ba da fa'idodi na dogon lokaci don kayan aikin gini. Ƙimar sake zagayowar rayuwa (LCA) da ƙididdigar farashi suna nuna cewa manyan abubuwan haɗin gwiwa suna rage kashe kuɗi da aiki akan lokaci. Misali, mannen da aka yi amfani da shi a cikin insulating sifofin kankare (ICFs) suna ba da gudummawa ga rage farashin makamashi da ingantaccen karko. Yayin da farashin farko na masu ɗaure masu inganci na iya zama kamar mafi girma, ikon su na jure lalacewa da damuwa na muhalli yana rage buƙatar sauyawa akai-akai. Wannan dorewa ba kawai yana adana kuɗi ba har ma yana rage raguwar lokaci, yana tabbatar da cewa ayyukan gine-gine sun kasance a kan jadawalin. Bugu da ƙari, lokacin aiki na kayan aikin gini yana da sama da kashi 90% na tasirin muhallinsa. Ta hanyar zabar kayan abin dogara, ƙwararru za su iya haɓaka dorewa yayin samun ƙimar farashi.

Gujewa Ƙarƙashin Ƙarfafa, Zaɓuɓɓuka marasa tsada

Masu ɗawainiya masu ƙarancin farashi sau da yawa suna bayyana sha'awa saboda iyawar su, amma suna iya haifar da al'amura masu mahimmanci. Waɗannan naúrar yawanci ba su da ƙarfi da dorewa da ake buƙata don aikace-aikace masu nauyi. Bayan lokaci, za su iya lalata, sassauta, ko kasawa a ƙarƙashin damuwa, suna lalata aminci da aikin kayan aikin gini. Sauyawa akai-akai da gyare-gyare masu alaƙa da ƙananan injuna na ƙara yawan farashi da rushe ayyuka. Bugu da ƙari, ƙayyadaddun kayan aiki na iya haifar da rarraba kaya mara daidaituwa, wanda ke hanzarta lalacewa akan abubuwan kayan aiki. Masu sana'a yakamata su ba da fifikoinganci akan farashidon guje wa wadannan matsaloli da kuma tabbatar da dorewar injinsu.

Zaɓuɓɓuka masu Tasiri don Kayan Aikin Gina Tsawon Rayuwa

Magani masu tsada ba koyaushe yana nufin zabar zaɓi mafi arha ba. Madadin haka, sun haɗa da zaɓar kayan aiki da ayyuka waɗanda ke daidaita araha tare da aiki. Binciken kasuwa yana nuna dabaru da yawa don cimma wannan daidaito:

- Gyara kayan aiki yana kara tsawon rayuwar injina, yana rage buƙatar sabbin masana'antu.

- Haɓaka tsofaffin kayan aiki yana inganta ƙarfin kuzari kuma yana rage yawan mai.

- Sake amfani da kuma zubar da kayan da ya dace na inganta sarrafa sharar gida da dorewa.

- Haƙƙin samo kayan ɗamara yana tabbatar da dorewa ba tare da ɓata iyakokin kasafin kuɗi ba.

Ta hanyar yin amfani da waɗannan ayyuka, ƙwararrun gine-gine na iya haɓaka dadewa na kayan aikin su yayin da suke kiyaye ƙimar farashi. Zaɓin madaidaicin sanda da goro, alal misali, yana tabbatar da ingantaccen aiki kuma yana rage yuwuwar gazawar da ba zato ba tsammani.

Gujewa Kurakurai Jama'a

Hana Kayayyakin da basu dace ba

Amfanirashin daidaituwa kayandon hex bolts da goro na iya haifar da lalacewa da wuri, lalata, ko gazawa. Masu sana'a na gine-gine dole ne su tabbatar da dacewa da kayan aiki don kula da mutuncin kayan ɗamara. Misali, haɗa bakin karfe tare da goro na ƙarfe na carbon na iya haifar da lalatawar galvanic, musamman a cikin yanayi mai ɗanɗano ko na ruwa. Wannan yana faruwa ne lokacin da ƙananan ƙarfe guda biyu suka haɗu, suna haifar da amsawar lantarki.

Don hana rashin daidaituwa, ƙwararrun ya kamata:

- Abubuwan daidaitawa tare da juriyar lalata iri ɗaya.

- Tabbatar da maki kayan abu da ƙayyadaddun bayanai kafin shigarwa.

- Yi amfani da haɗin gwiwar masana'anta da aka ba da shawarar don ingantaccen aiki.

Tukwici: Koyaushe tuntuɓi ginshiƙi masu dacewa da kayan don guje wa kurakurai masu tsada da tabbatar da haɗin gwiwa mai dorewa.

Tabbatar da Madaidaicin Ƙarfin lodi

Ba daidai bazabar iya aikikuskure ne na kowa wanda ke lalata aminci da aikin kayan aiki. Hex bolts da goro dole ne su yi tsayin daka da sojojin da aka yi yayin aiki ba tare da nakasu ko gazawa ba. Zaɓin kayan ɗamara tare da ƙarancin ƙarfin hujja ko ƙarfi na iya haifar da gazawar bala'i.

Masu sana'a ya kamata:

- Yi lissafin matsakaicin buƙatun kaya don aikace-aikacen.

- Koma zuwa ma'auni na masana'antu, kamar ASTM ko ISO, don ƙimar lodi.

- Zaɓi masu ɗaure tare da tazarar aminci don lissafin matsalolin da ba zato ba tsammani.

Lura: Abubuwan da ake ɗauka da yawa na iya haifar da zaren zare ko ƙara tsawo, rage kwanciyar hankali gaba ɗaya.

Lissafin Harkokin Muhalli

Yin watsi da yanayin muhalli yayin zaɓin fastener na iya haifar da lalata, rage ƙarfi, ko gazawar inji. Wuraren gine-ginen galibi suna fallasa abubuwan damfara ga danshi, sinadarai, da yanayin zafi, wanda zai iya lalata kayan cikin lokaci.

Don magance abubuwan muhalli:

- Yi amfani da sutura masu jure lalata, kamar galvanization ko plating na zinc, a cikin yanayi mai laushi ko rigar.

- Zaɓi bakin karfe ko gami da ƙarfe don matsanancin zafin jiki ko mahalli masu haɗari.

- A kai a kai duba manne don alamun lalacewa ko lalata.

Pro Tukwici: Yi la'akari da ƙayyadaddun ƙalubalen muhalli na wurin aikin don tabbatar da masu ɗaure su kula da aikin su da tsawon rai.

Zaɓin madaidaicin hex bolt da goro yana da mahimmanci don tabbatar da tsawon rai da aikin kayan aikin gini. Kayan abu, ƙarfi, girman, sutura, da farashi duk suna taka muhimmiyar rawa wajen tantance amincin masu ɗaure. Maɗaukaki masu inganci ba wai kawai haɓaka mutuncin tsarin ba amma kuma suna rage buƙatun kulawa da raguwar aiki.

- Ana hasashen kasuwar ƙera masana'antu za ta wuce dala biliyan 125 nan da shekarar 2029, wanda ke nuna mahimmancin haɓakar su a cikin gini da injina.

- Kwararru suna ba da shawarar dubawa na yau da kullun da kuma kula da na'urorin haɗi don tabbatar da kyakkyawan aiki da kuma hana gazawar da ba zato ba tsammani.

Ta hanyar ba da fifikon inganci da yin zaɓin da aka sani, ƙwararru za su iya haɓaka ingancin kayan aiki da rage ɓarna mai tsada.

FAQ

Menene mafi kyawun abu don hex bolts a cikin ginin waje?

Bakin karfe shine mafi kyawun zaɓi don ginin waje. Juriyarsa na lalata yana tabbatar da dorewa a cikin yanayi mai laushi ko rigar. Don ayyuka masu tsada, carbon karfe tare da kayan kariya kamar galvanization kuma na iya yin kyau.

Ta yaya ƙwararru za su iya tabbatar da dacewa da ƙulla da goro?

ƙwararru yakamata su dace da kayan, farar zaren, da ƙayyadaddun girman girman. Yin amfani da kayan aiki kamar calipers da ma'aunin zaren yana tabbatar da ingantattun ma'auni. Tuntuɓar shawarwarin masana'anta kuma yana taimakawa guje wa rashin daidaituwa.

Me yasa sutura suke da mahimmanci ga hex bolts da goro?

Rubutun yana kare manne daga lalata, yana kara tsawon rayuwarsu. Zinc plating, galvanization, da phosphate coatings suna ba da matakan kariya daban-daban. Zaɓin ya dogara da bayyanar muhalli da buƙatun aikace-aikace.

Sau nawa ya kamata a duba na'urorin haɗi?

Yakamata a rika duba abubuwan dauri a kai a kai, musamman a cikin matsananciyar damuwa ko lalatattu. Binciken wata-wata don alamun lalacewa, lalata, ko sassautawa yana taimakawa kiyaye amincin kayan aiki da aiki.

Shin manyan kayan ɗaurin ƙarfi sun zama dole don duk aikace-aikacen gini?

Maɗaukakin ƙarfi mai ƙarfi suna da mahimmanci don kaya masu nauyi ko matsanancin yanayi, kamar haɗin ginin ƙarfe ko injina masu nauyi. Don aikace-aikace masu sauƙi, madaidaitan madaidaitan madaidaicin na iya isa, in dai sun cika buƙatun kaya.

Lokacin aikawa: Afrilu-25-2025